Umucu wethusi othininiiyinsimbi enongqimba lukathayela ebusweni bomucu wethusi. Inqubo yokukhiqiza i-copper strip efakwe ethini ihlukaniswe ngezinyathelo ezintathu: ukwelashwa kwangaphambili, ukucwenga kwe-tin kanye nokwelashwa ngemuva kokwelashwa.

Ngokwezindlela ezihlukene zokucwenga ithini, ingahlukaniswa ibe yi-electroplating kanye ne-hot-dip plating. Kunomehluko phakathi kwe-electroplated copper strip kanye ne-hot-dipi-copper stripezicini eziningi.

I. Umgomo wenqubo

1) Electroplating tinning: Isebenzisa isimiso electrolysis ukusebenzisaumugqa wethusinjenge-cathode ne-tin njenge-anode. Kusixazululo se-electroplating esiqukethe i-tin ion, ama-tin ion ayancishiswa futhi afakwe ebusweni bomucu wethusi ukuze enze ungqimba olufakwe ithini ngokusebenzisa isenzo samanje esiqondile.

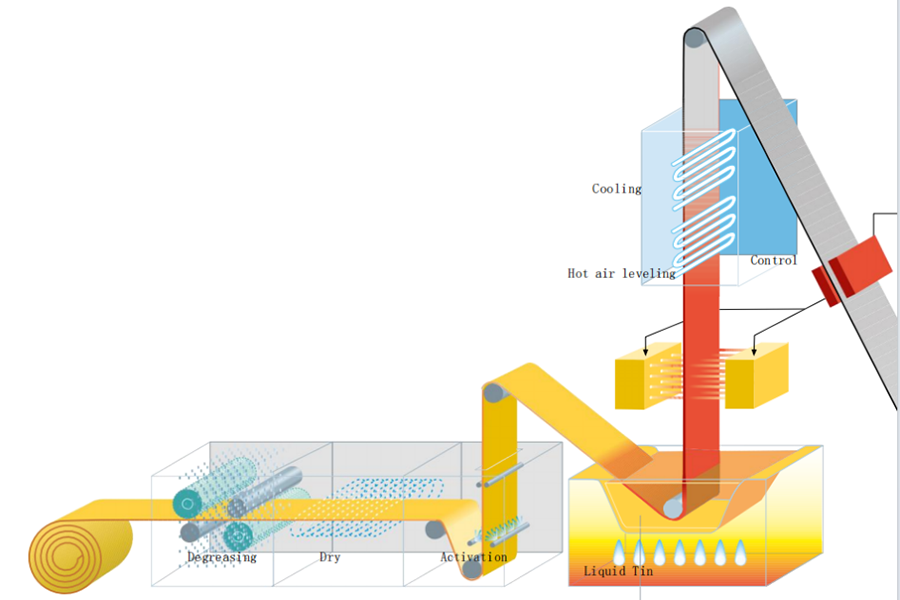

2) I-Hot-dip tinning: Iwukucwilisaumugqa wethusioketshezini lwethini oluncibilikisiwe. Ngaphansi kwezimo ezithile zokushisa nezimo zesikhathi, uketshezi lukathayela lusabela ngokomzimba nangamakhemikhali ngobuso bomucu wethusi ukuze kwakhe ungqimba lukathini ebusweni bomucu wethusi.

II. Izici zokumboza:

1) Ukufana kokugqoka

A) I-Electroplating tinning: Ukufana kokunamathela kuhle, futhi kungakha ungqimba olufana noluthambile lokuthayela phezu kwendawoumugqa wethusi. Ikakhulukazi imichilo yethusi enezimo eziyinkimbinkimbi nezindawo ezingalingani, ingaphinde ihlanganise kahle, efanelekile izimo zokufaka isicelo ezinezidingo eziphezulu zokufana kokugqoka.

B) I-hot-dip tinning: Ukufana kwe-coating kubi kakhulu, futhi ukujiya okungalingani kungase kwenzeke emakhoneni nasemaphethelweni e-coat.umugqa wethusi. Kodwa-ke, kwezinye izikhathi lapho izimfuneko zokufana kwe-coating zingaqinile kakhulu, umthelela mncane.

2) Ukuqina kwe-coating:

A) I-Electroplating tinning: Ugqinsi lokumboza luncane, ngokuvamile luphakathi kwama-microns ambalwa namashumi ama-microns, futhi lungalawulwa ngokunembile ngokwezidingo ezithile.

B) I-Hot-dip tinning: Ugqinsi oluwugqinsi luvame ukuba lugqinsi, ngokuvamile luphakathi kwamashumi ama-microns namakhulu ama-microns, olunganikeza ukumelana nokugqwala okungcono kanye nokumelana nokugugaimichilo yethusi, kodwa ingase ingafaneleki kwezinye izinhlelo zokusebenza ezinemikhawulo eqinile ekugqileni.

III. Ukusebenza kahle kokukhiqiza

1) I-Electroplating tin plating: Inqubo yokukhiqiza iyinkimbinkimbi, idinga izinqubo eziningi ezifana nokwelashwa kwangaphambili, i-electroplating, kanye nokwelashwa kwangemva kokwelashwa. Isivinini sokukhiqiza sihamba kancane futhi asifanele ukukhiqizwa okukhulu nokusezingeni eliphezulu. Kodwa-ke, kwezinye izidingo ze-batch ezincane nezenziwe ngezifiso, i-electroplating tin plating inokuguquguquka okuhle.

2) I-Hot-dip tin Plating: Inqubo yokukhiqiza ilula. Inqubo ye-tin plating ingaqedwa ngokucwilisa i-umugqa wethusioketshezini lwethini. Isivinini sokukhiqiza siyashesha futhi singahlangabezana nezidingo zokukhiqiza okukhulu.

IV. Amandla okubopha:

I-1) I-Electroplating tin plating: Amandla okubopha phakathi kwe-coating kanye ne-umugqa wethusii-substrate inamandla. Lokhu kungenxa yokuthi ama-ion tin akha izibopho zamakhemikhali nama-athomu angaphezulu komugqa wethusi ngaphansi kwesenzo senkambu kagesi phakathi nenqubo ye-electroplating, okwenza ukunamathela kube nzima ukuwa5.

2) I-Hot-dip tin Plating: Amandla okubopha nawo mahle, kodwa kwezinye izimo, ngenxa yokusabela okuyinkimbinkimbi phakathi koketshezi lukathayela kanye nobuso bethayela.umugqa wethusiphakathi nenqubo yokucwenga kwe-hot-dip, ezinye izimbotshana ezincane noma amaphutha angase avele, athinte amandla okubopha. Kodwa-ke, ngemva kokwelashwa okufanele, amandla okubopha we-hot-dip tin plating angahlangabezana nezidingo zezinhlelo zokusebenza eziningi.

V. Ukumelana nokugqwala:

I-1) I-Electroplating tinning: Ngenxa yokwemboza okuncane, ukumelana nokugqwala kwayo kubuthakathaka. Kodwa-ke, uma inqubo ye-electroplating ilawulwa kahle futhi kufanele ukwelashwa kwangemva kwesikhathi, njengokudlula, kwenziwa, ukumelana nokugqwala kwe-corrosion resistance.i-copper stripingathuthukiswa futhi

2) I-Hot-dip tinning: I-coating ishubile, enganikeza ukuvikeleka okungcono kokumelana nokugqwala kweumugqa wethusi. Ezimweni ezinzima zemvelo, njengezindawo zegesi ezinomswakama nezonakalisayo, inzuzo yokumelana nokugqwala kwediphu elishisayo.i-copper stripkusobala kakhulu5.

VI. Izindleko

1) I-Electroplating tinning: I-investimenti yokutshala imali incane uma kuqhathaniswa, kodwa ngenxa yenqubo yokukhiqiza eyinkimbinkimbi, idla ugesi owengeziwe kanye nama-reagents amakhemikhali, futhi inezidingo eziphezulu zendawo yokukhiqiza kanye nabaqhubi, ngakho-ke izindleko zokukhiqiza ziphezulu uma kuqhathaniswa.

2) I-Hot-dip tinning: I-investimenti yemishini inkulu, futhi iziko lokushisa eliphezulu nezinye izinto zokusebenza zidinga ukwakhiwa, kodwa inqubo yokukhiqiza ilula futhi ukusetshenziswa kwempahla eluhlaza kuncane kakhulu, ngakho-ke izindleko zeyunithi zingase zibe phansi uma kuqhathaniswa nokukhiqizwa okukhulu.

Ukukhetha ai-copper stripifanele isimo sakho sohlelo lokusebenza idinga ukucatshangelwa okuphelele kwezici eziningi ezifana nezakhiwo zikagesi, izakhiwo zemishini, ukumelana nokugqwala, inqubo yokukhiqiza, izindleko nokuvikelwa kwemvelo. Ngokwezidingo ezithile, linganisa ubuhle nobubi bazo zonke izici bese ukhetha ezifanele kakhului-copper stripukuqinisekisa ukusebenza kanye nekhwalithi yomkhiqizo.

Isikhathi sokuthumela: Sep-18-2024